Drilling & Completions Fueling

GTUIT Direct Fueling

GTUIT leads the industry towards greater efficiency and utilization of available wellsite resources. We are fueling gas fired and dual fuel frac fleets and drilling rigs by conditioning field gas at the well site and delivering it directly to the engines powering operations. All equipment in the GTUIT Direct Fueling System is designed to be mobile and modular, allowing the ability to run parallel systems to meet fueling requirements for any hydraulic fracturing fleet or drilling setup no matter the supplied gas chemistry, horsepower requirement, or basin. The benefits of this new model in wellsite fuel conditioning & delivery cannot be overstated, with huge ESG and economic benefits.

Based on raw gas parameters, composition, and flow rate, the correct combination of GTUIT Technology can be specified to meet your requirements.

GTUIT Direct fueling: Key benefits

- Substantial savings over both straight diesel power and CNG blending in dual-fuel engines

- GTUIT’s patent-pending technology provides consistent gas quality for dual-fuel and gas-fired engines regardless of the quality of the raw associated field gas

- Reduced wellsite traffic from both diesel and CNG fuel providers resulting in safer and simpler wellsite operations

- Measurable ESG benefits

- Numerous wellsite applications including dual-fuel frac power, power for drilling operations, and grid power

- GTUIT 24/7 operational monitoring & service ensuring 99+% uptime

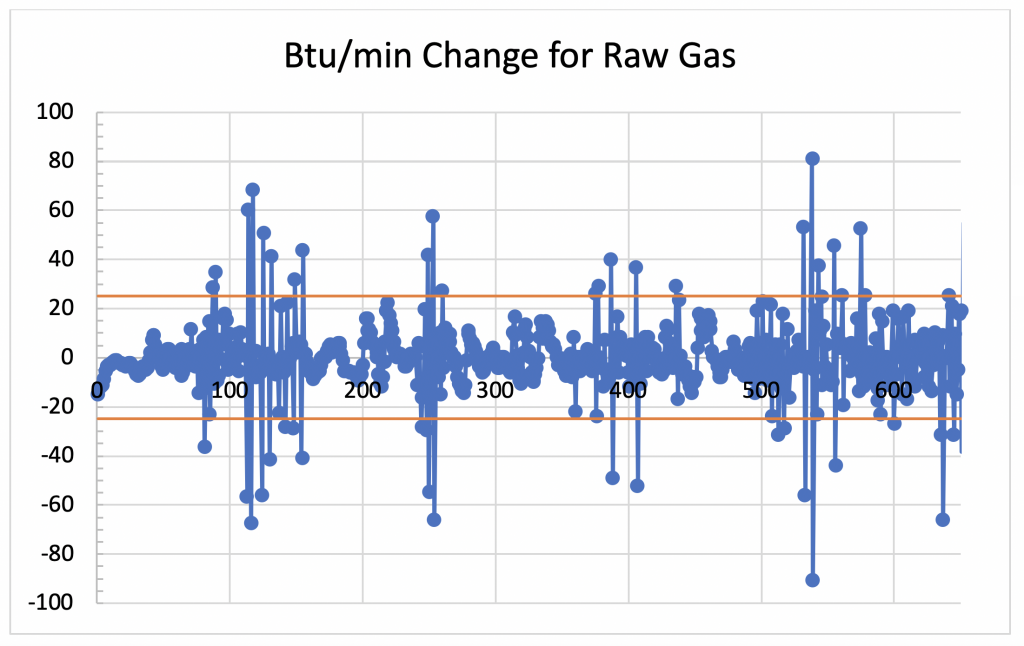

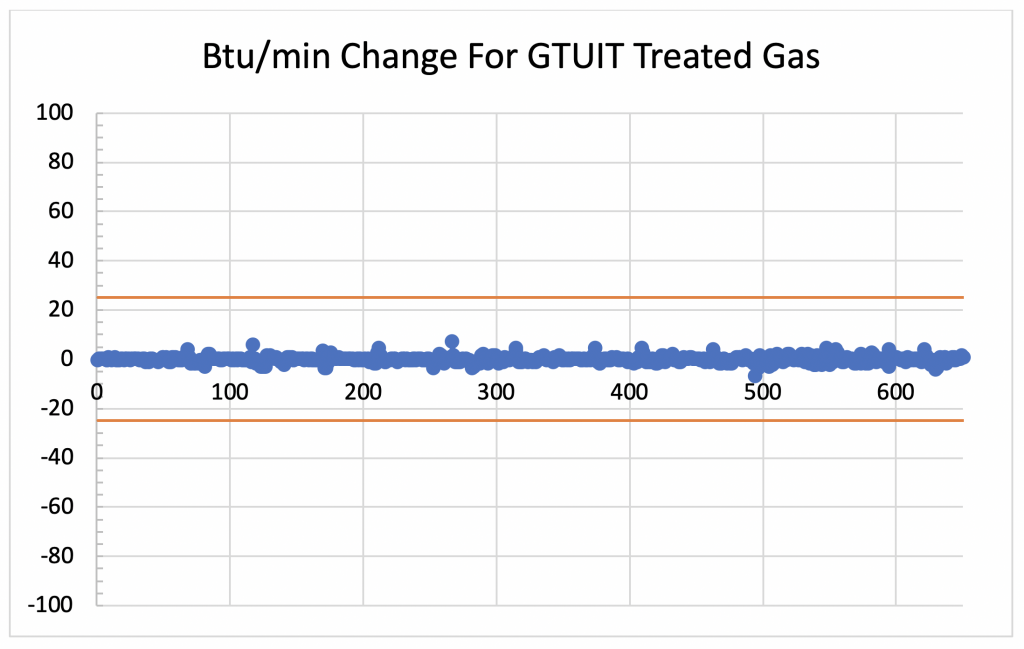

Real Results Using GTUIT Technology

GTUIT’s patent-pending technology acts like a fuel filter for raw fuel gas, producing consistent quality gas regardless of flow or ambient conditions.

Measured Gas Heating Value Rate of Change

GTUIT Technology Benefits

Mobile

- Mobile units can be quickly moved to another site

- Takedown and set up in as little as 24 hours

- Systems can remain in place for as long as required

Safe

- Designed, manufactured, and tested using ISO 9001 QMS standards

- Class 1 Division 2 electrical standards, fail closed isolation and auto shutdown

- Proven record of safety with TRIR of 0.0 and a Mod rate of 0.87

Modular

- Scalable systems with significant turndown capabilities for flexible capacity

- Modules can be combined from 250 MCFD to over 10000 MCFD

- Trailer-mounted systems of 500, 1000 & 1500 MCFD available with larger systems purpose-built

Sustainable (ESG)

- Minimize flaring, incineration, and other wasteful practices

- Achieve and surpass corporate and legislative ESG targets

- Significantly reduce site CO2 and VOC emissions

Reliable

- Designed for and operating in all environments, from -40F to +110F

- Proprietary automation control and remote monitoring

- Equipment proven uptime over 98%

Profitable

- Monetize product which is otherwise wasted

- Replace diesel and other fuel costs for huge savings

- Direct returns on turn-key operations and rapid ROI on equipment sales

Revenue Streams

Conditioned Field Gas

Conditioned field gas recovered after the removal of Natural Gas Liquids (NGLs) may be available to be monetized using one or more of the following methods:

- Replacement of diesel with conditioned field gas yields huge cost savings

- Conditioned field gas export through sales pipelines

- Conditioned field gas export through virtual pipelines or mobile LNG/CNG

- Gas power generation and sale to the power grid or local industry

Natural Gas Liquids (NGLs)

Natural Gas Liquids (NGLs) recovered from gas conditioning may be available to be monetized using one or more of the following methods:

- NGLs can be transported by truck and sold to fractionation facilities

- Injection of NGLs into oil export pipeline will swell oil export, improve oil API and even replace diluent

- NGL power generation and sale to the power grid or local industry